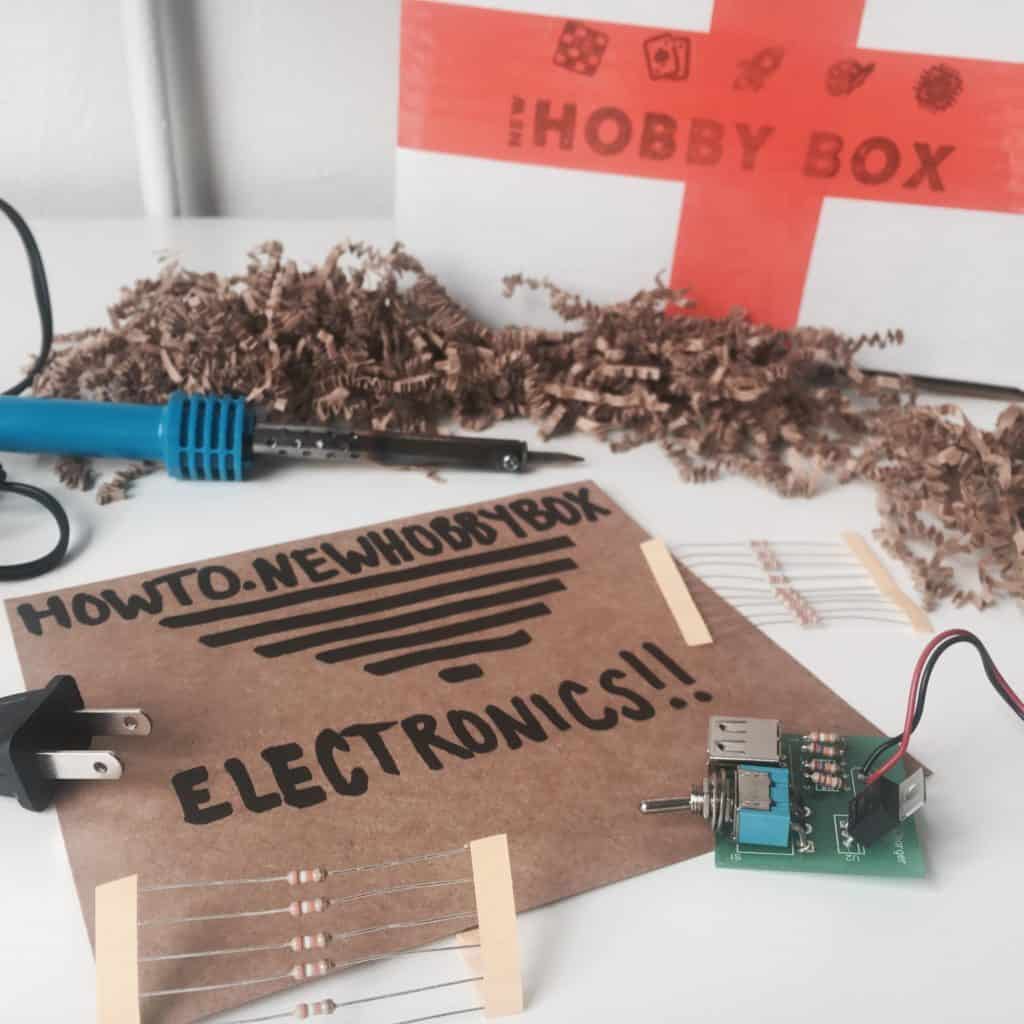

iPhone and Android users rejoice – this electronics kit will make sure your phone never hits 0% charge again. Or any device that has a USB port for that matter. That’s right, we’ve got everything you need to learn how to make a portable charger powered by batteries; from materials, and where to get them, to a highly visual instruction manual.

And In addition to building your own power bank, you’ll begin demystifying electronics and learn how to solder in the process.

If you’ve never soldered before, don’t worry, you’ll pick it up quickly. Before this kit, I had never soldered before, and the charger worked like a charm – and soldering was super fun.

When we used to make and sell this electronics kit as part of our subscription box business, this DIY USB charger was one of only two kits that we sent out twice, the other being our lock picking kit; and we ended up sending them twice because they were super popular with our subscription customers.

We would get emails all the time asking if we could sell the electronics kit outside of our subscription – so you know this is a good one.

SUPPLIES NEEDED TO MAKE PORTABLE USB CHARGER

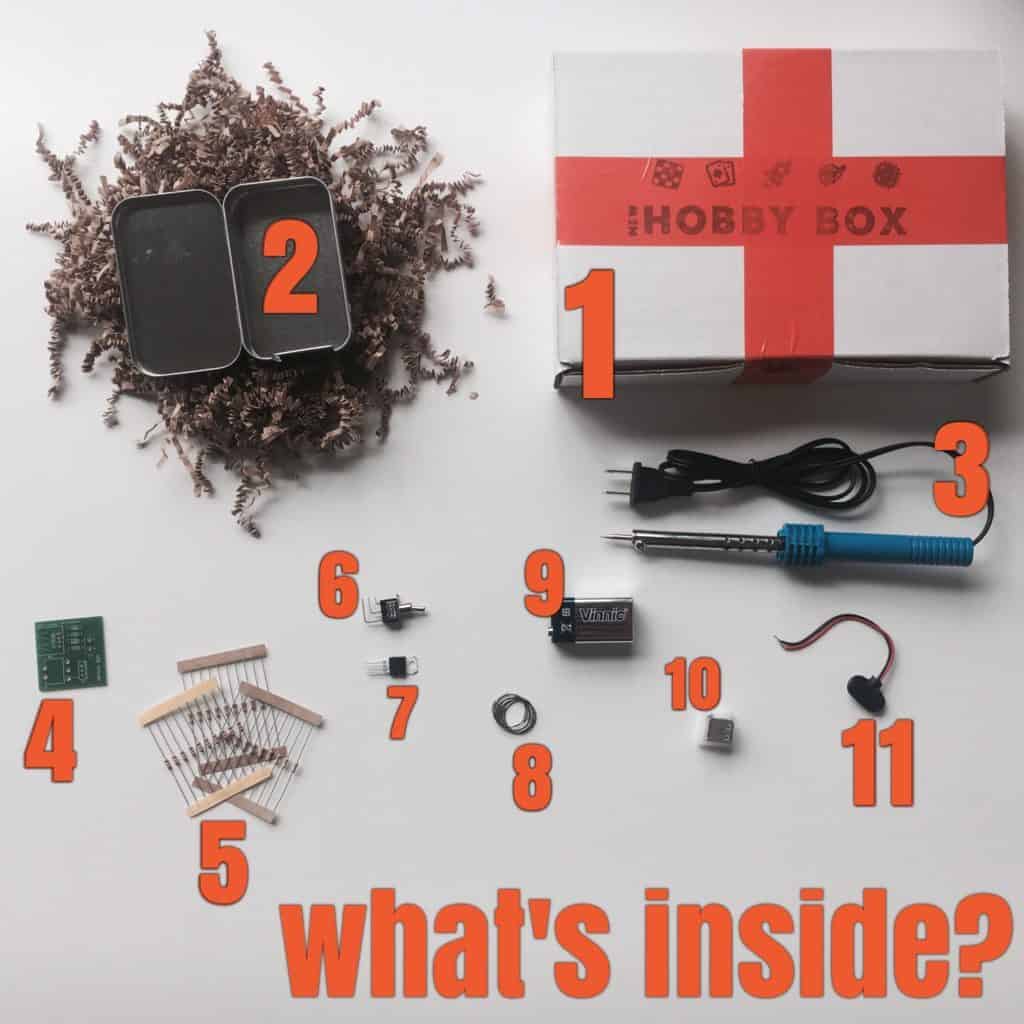

Just a few notes about supplies – you’ll find all the items we used in this tutorial (we swapped out our circuit board for something else – it’s number 4 in the table and image below.) We’ve dropped the links to each item on each item’s name, in case you need to source it.

Also, you don’t have to use an Altoids tin – really we just say some sort of mint tin because the size is perfect for the casing.

It doesn’t even have to be a mint tin, just try to get something that doesn’t have too much room inside – you don’t want your circuit board bouncing around inside the case.

Parts List for DIY USB Charger

| Image Number | Part & Shopping Link | Quantity |

| 1 | Cardboard Box | 1 |

| 2 | Altoids Tin (Any Tin) | 1 |

| 3 | 60W Soldering Iron | 1 |

| 4 | Solderable Circuit Board | 1 |

| 5 | 22kΩ Resistor | 2 |

| 5 | 27kΩ Resistor | 1 |

| 5 | 39kΩ Resistor | 1 |

| 6 | Small Switch | 1 |

| 7 | 7805 Voltage Regulator | 1 |

| 8 | Lead-Free Soldering Wire | 1 |

| 9 | 9V Battery | 1 |

| 10 | USB Socket | 1 |

| 11 | 9V Battery Clip | 1 |

Other Tools and Items You’ll Need

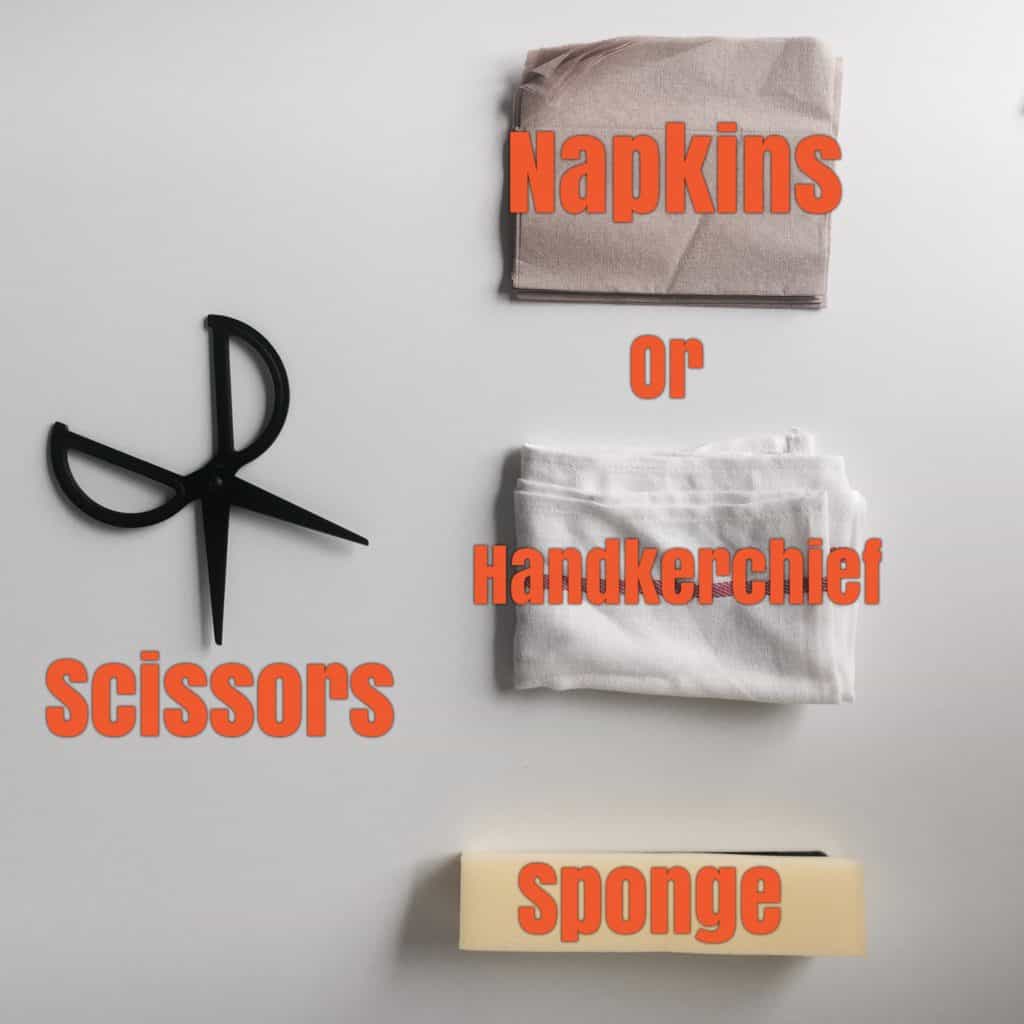

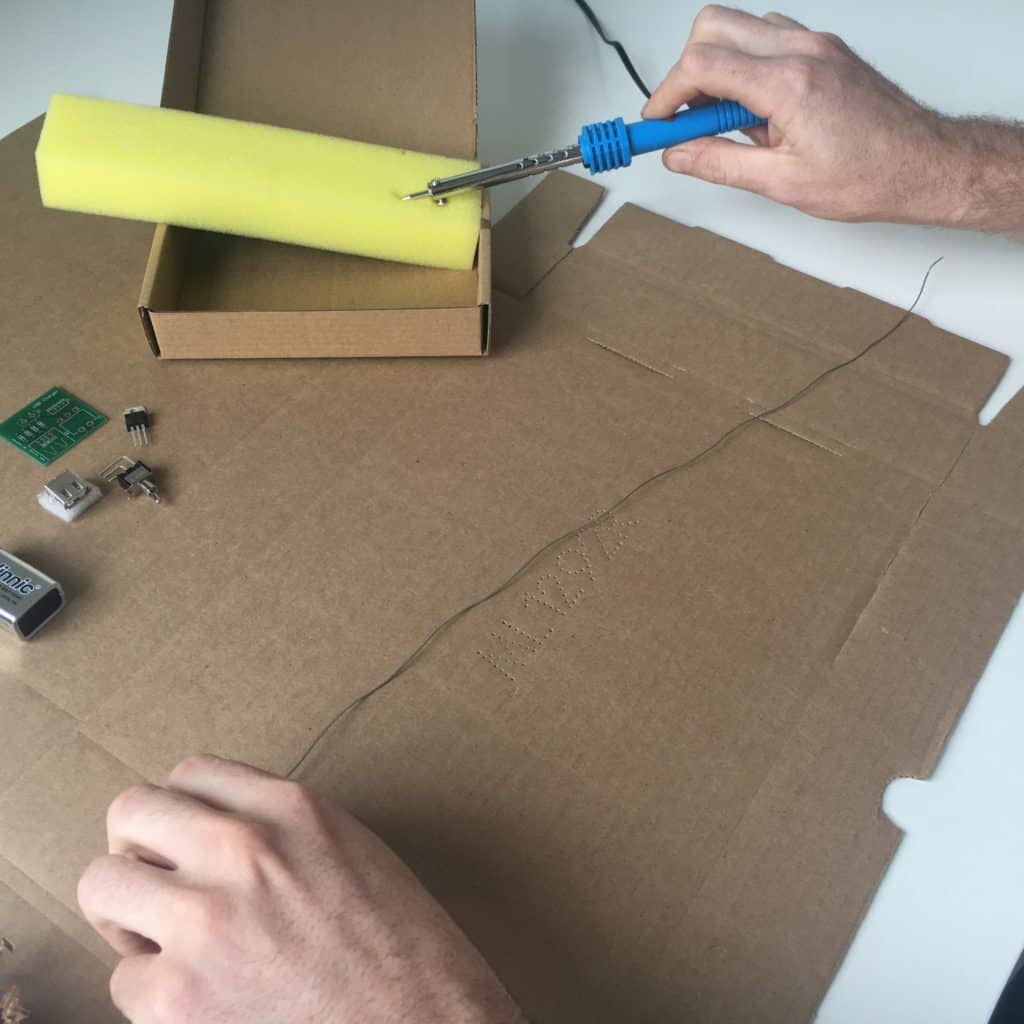

A FLAT TEMPORARY SURFACE

A flattened-out cardboard box works like a charm. Just don’t let your soldering iron sit on it directly for too long. You’ll want a location that can get dirty or messed up.

Make sure you set it up on a sturdy table or flat area. The soldering iron get’s extremely hot, so you don’t want to burn a nice chunk out of your dining room table.

AN OLD SPONGE AND NAPKINS

Grab whatever’s lying around the house and get it moist – you’ll dip the soldering iron tip in it to clean the tip and it’s also a great place to set the iron when you aren’t using it. Just note that you won’t want to reuse it for doing the dishes afterward.

Keep a napkin or handkerchief handy during this as well – just in case any sort of mess arises.

SCISSORS, PLIERS, OR WIRE CUTTERS

Any of those three will do the trick. This will be used to cut the excess wires on each component, and if you decide to use a metal tin, they will be used to cut out a section for the USB port.

THINGS TO NOTE BEFORE MAKING A USB CHARGER

Keep Airflow Moving

Okay, so this isn’t a tool or item, but proper ventilation is important, so we wanted to sneak it into this section. Use fans and open your windows.

You’ll want to make sure your soldering wire is lead-free – and even if it doesn’t contain lead, it’s still a good idea to not inhale any fumes. I used a bandanna – which probably didn’t do all that much – so please take care of yourself and get something more substantial.

How Do You Solder?

Soldering looks more complicated than it as. And seriously – it is an incredibly satisfying feeling when you realize that you soldered something correctly. The way the metal melts is awesome. You’ll see soon enough.

GENERAL CONCEPT OF SOLDERING:

Simply put, soldering is connecting two metal components by melting a piece of metal around both pieces that connect them.

A crude way to describe it, but that’s the basic principle.

One thing to note is that if you make a mistake, it’s not a big deal. You can easily melt it again and move the solder – so there is a lot of room to fix any error.

Don’t forget – the tip of the soldering iron gets crazy hot. Whatever you do, don’t touch it!

Okay, we got that out of the way – here’s a clip on how to solder correctly.

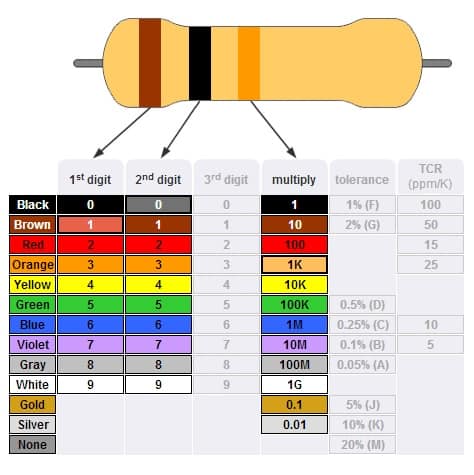

What Are Resistors?

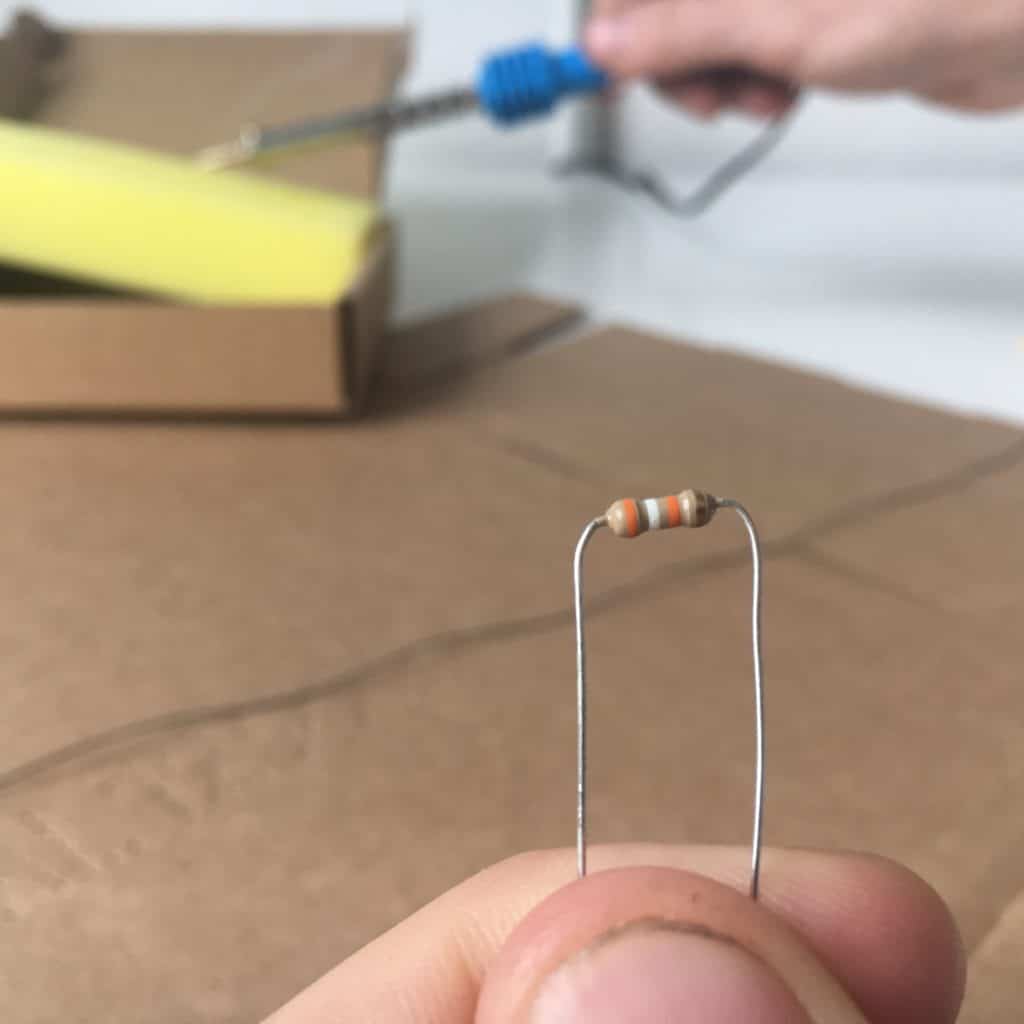

The wires with colorful bulbous mass in the middle are resistors. They help reduce current flow.

Pay close attention to the colors in the middle section. The colors help signify a number that corresponds to the ohms – and each resistor follows the color-coding system in this image.

RESISTORS USED IN THIS TUTORIAL

You’ll use three sets of resistors in this tutorial.

A 22kΩ, 27kΩ, and a 39kΩ. It’s probably been a while since you’ve seen any Greek, but Ω = Ohms, which uses the Greek Omega symbol, and gets its name Ohm in honor of German physicist Georg Ohm.

That’s been your 30-second history lesson on Ohms.

DECODING RESISTORS: QUIZ

Now, let’s look at the visual below – can you figure out which one it is based on the colors?

Using the color code guide, the orange-white-orange would be 3, 9, 1k or 39kΩ.

Pretty cool, right?

If you’re using a board like the one we use, the resistors will map as follows:

- R1 on the board is 39kΩ = orange/white/orange

- R2 and R3 on the board are 27kΩ = red/violet/orange

- R4 on the board is 22kΩ = red/red/orange

The rest of this kit is easier to digest at first glance.

The Rest of Your Kit

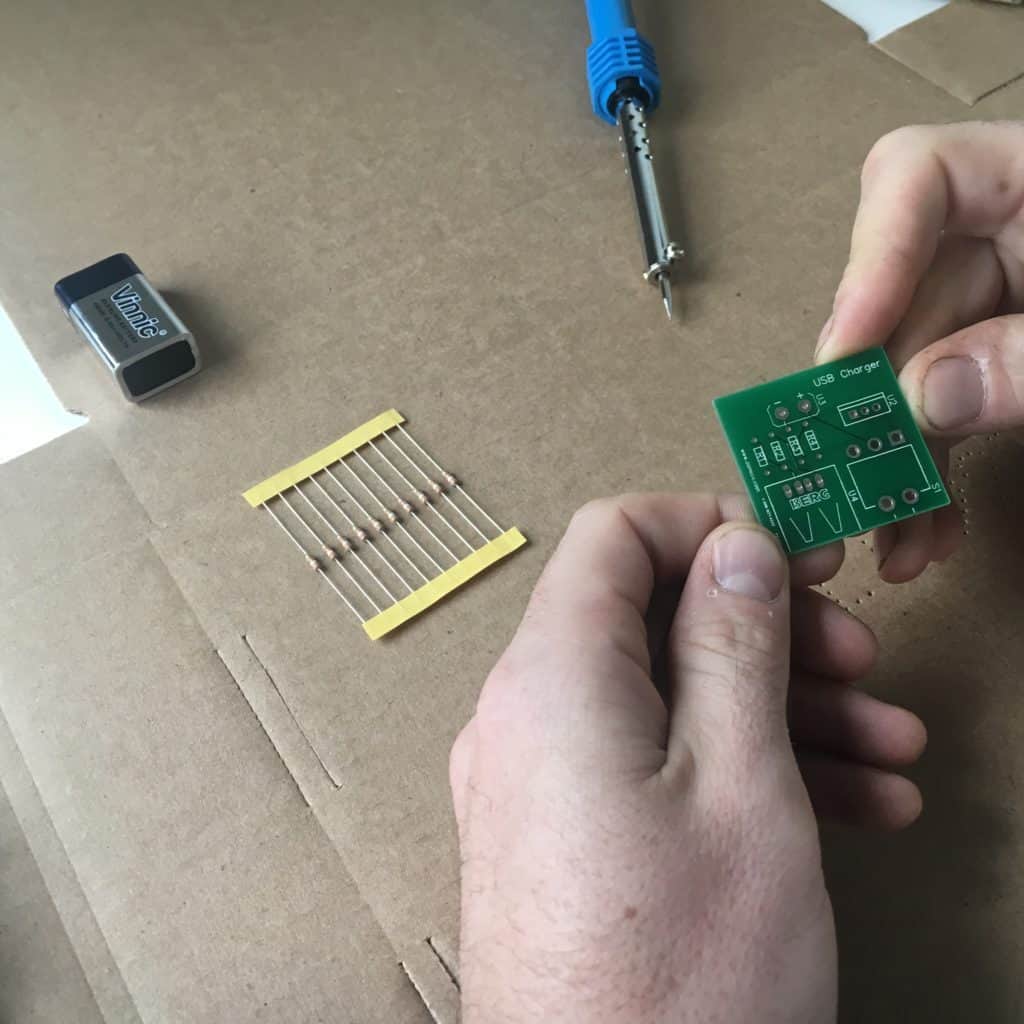

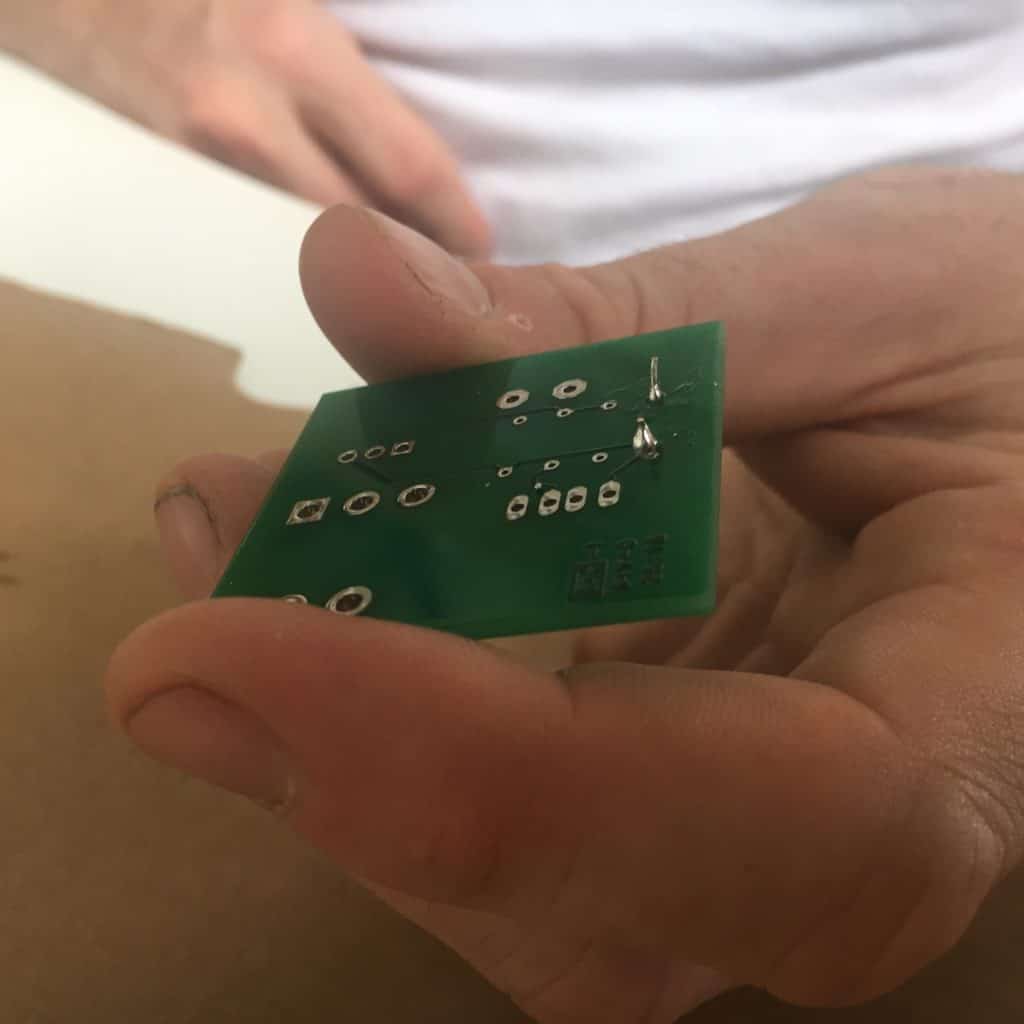

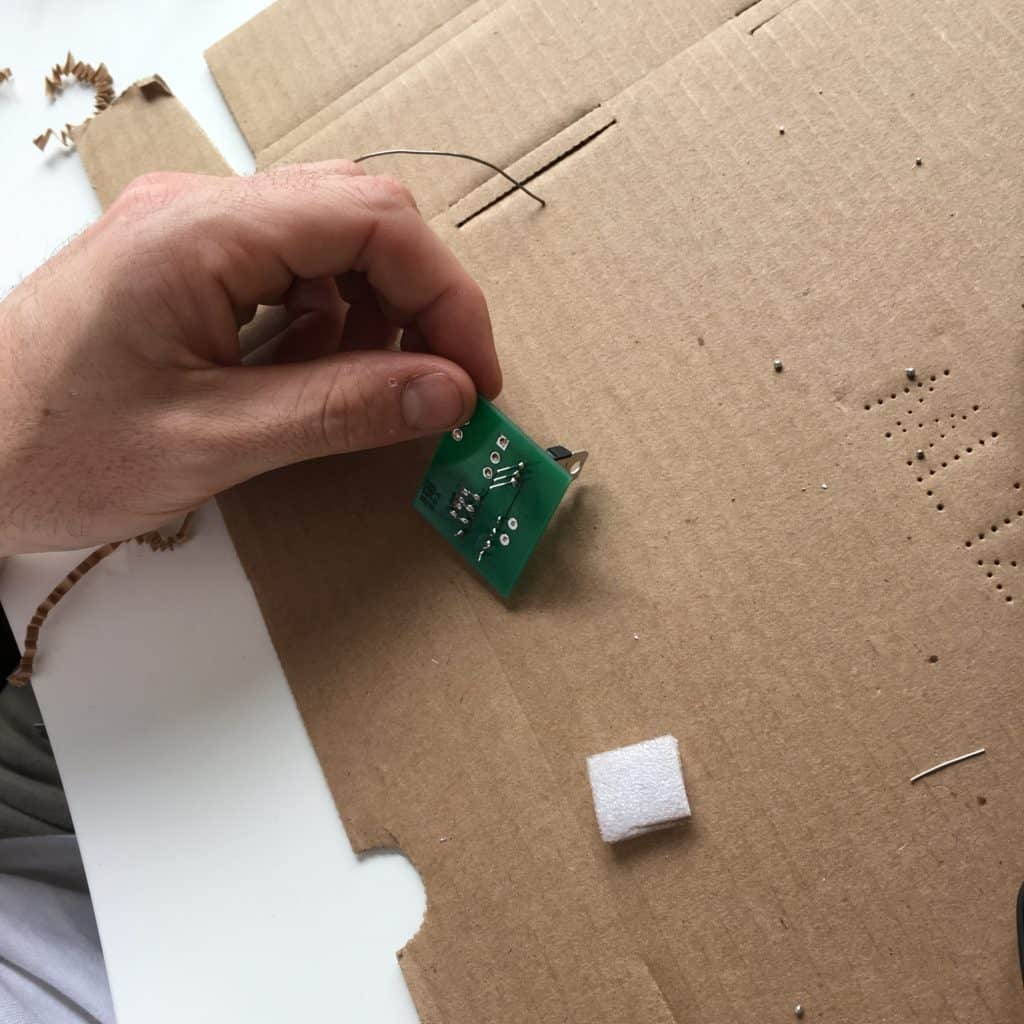

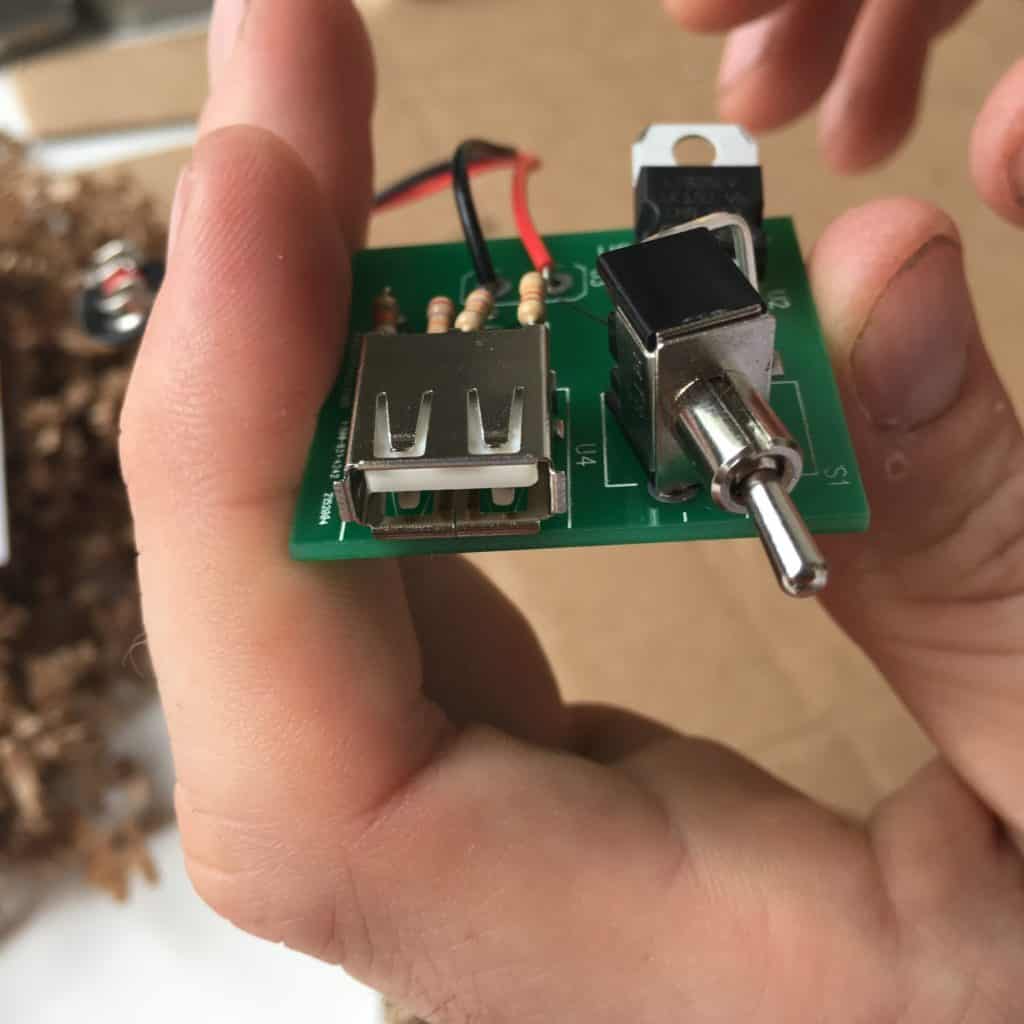

You have the board (green plate in the top middle) or you may be using a breadboard/prototyping board instead, that will be the component where all the pieces fit into.

You also have the voltage regulator which has three prongs on it. Additionally, a 9V battery with battery snaps, a USB connector, and a toggle switch to turn your kit on and off.

We now need to prep two things before we start soldering

Prepping Your Work Station

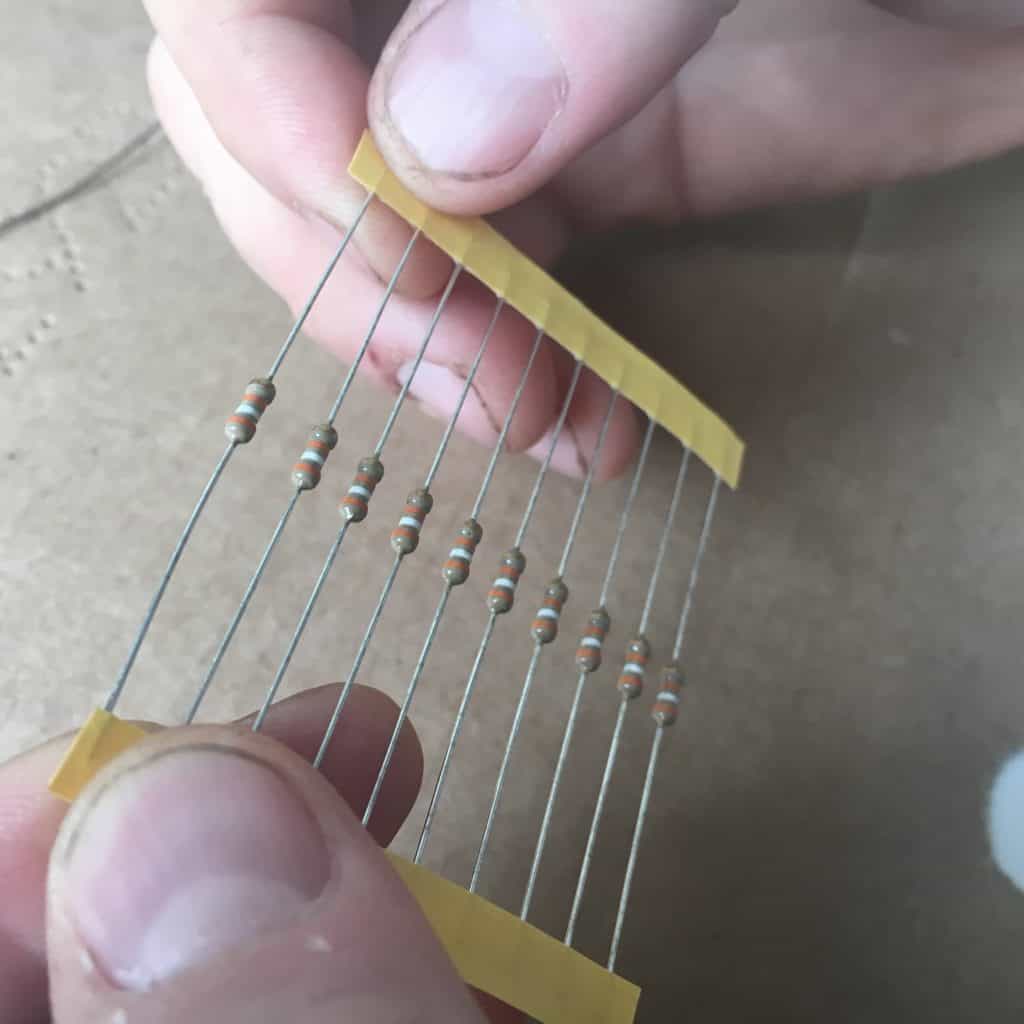

READY YOUR RESISTORS

We will start with the resistors first.

Resistor wires are extremely malleable, so don’t worry about bending them when you take them out of the tape, you can bend them back to whatever shape you need.

And if they somehow bend too much, don’t fret, that’s why they come in such large quantities.

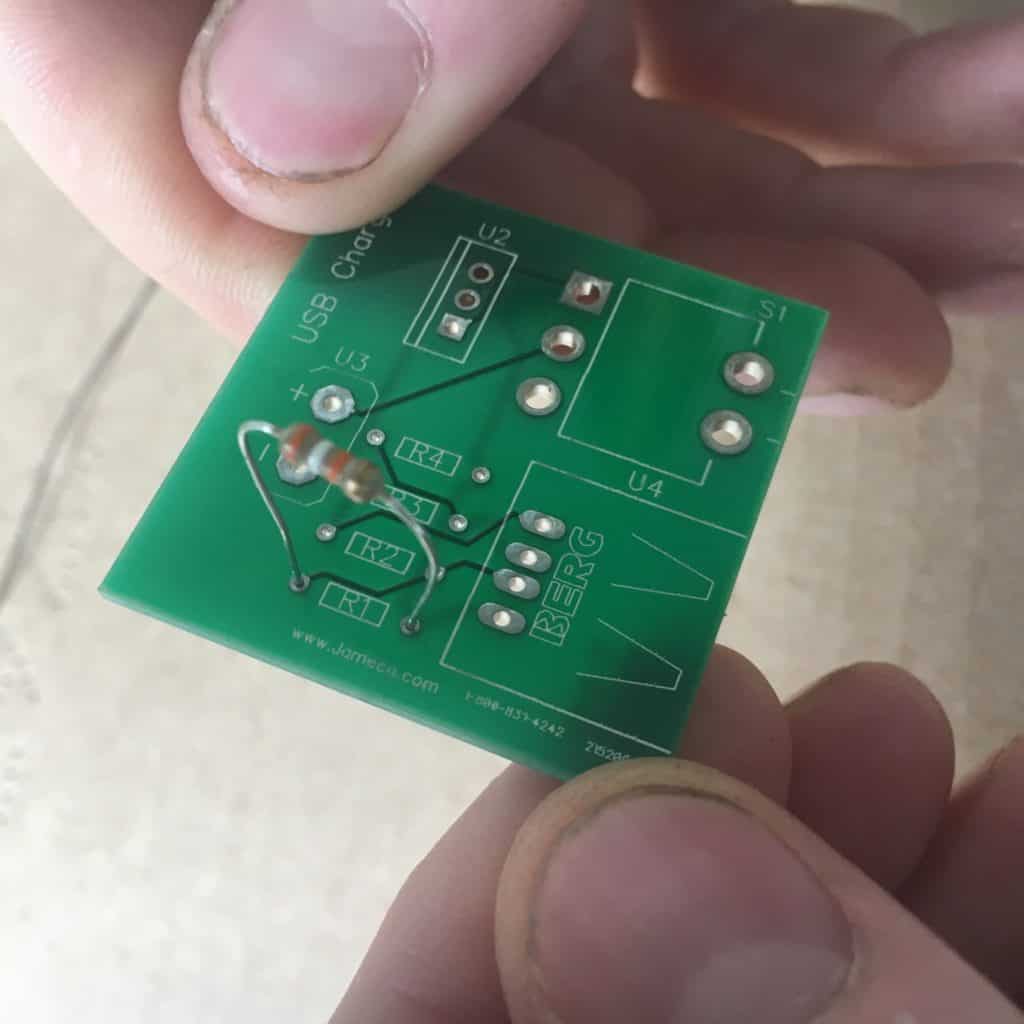

If you are using the same PCB (green circuit board pictured in my hand below) as I am, locate 4 items labeled on the board R1-R4.

Find your R1 resistor (orange/white/orange) and bend it into a “U” shape.

Pull resistor legs of R1 through the two holes on the front-side of the board.

Make sure you have the colorful part of the resistor on the front side of the board – this is the side where you can read the names of all the components like R1-R4.

It’s not a deal-breaker if you solder it upside down, it just makes it more difficult with the components facing up.

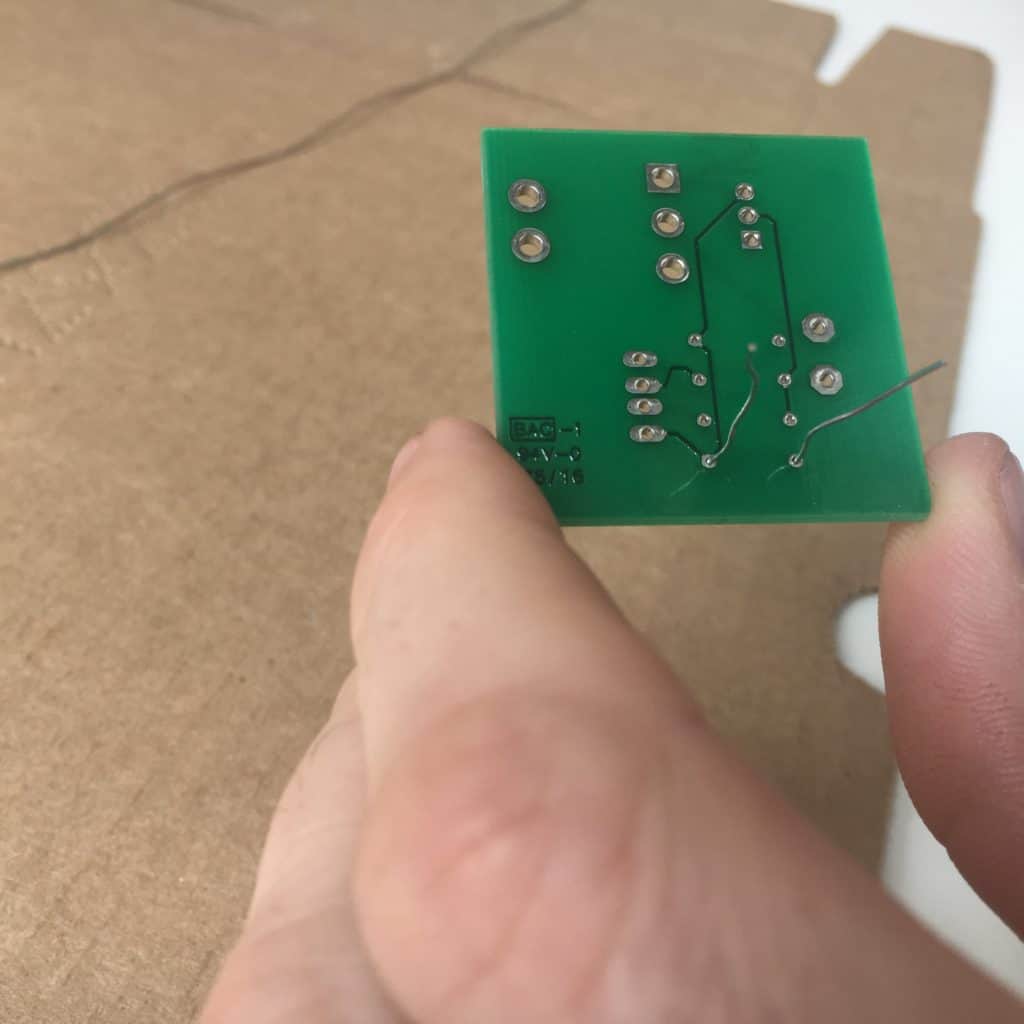

Pull the excess wire to the side of the board so you can see an opening between the wires and the board.

This will be the area we will fill with the soldering wire.

Plug in Soldering Iron

Make sure you have a damp sponge on hand. It’s time to unravel the soldering wire too.

Notice that the soldering iron in the photo below is touching the damp sponge – keep it moist!

Your station is clear and set up. You know what resistors are and now have all your items fired up.

Okay – I think we’re ready. Let’s rock.

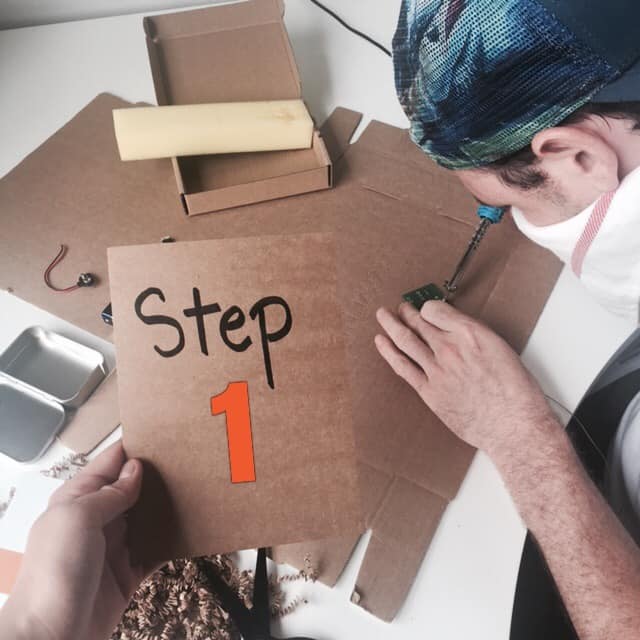

HOW TO MAKE A PORTABLE USB CHARGER

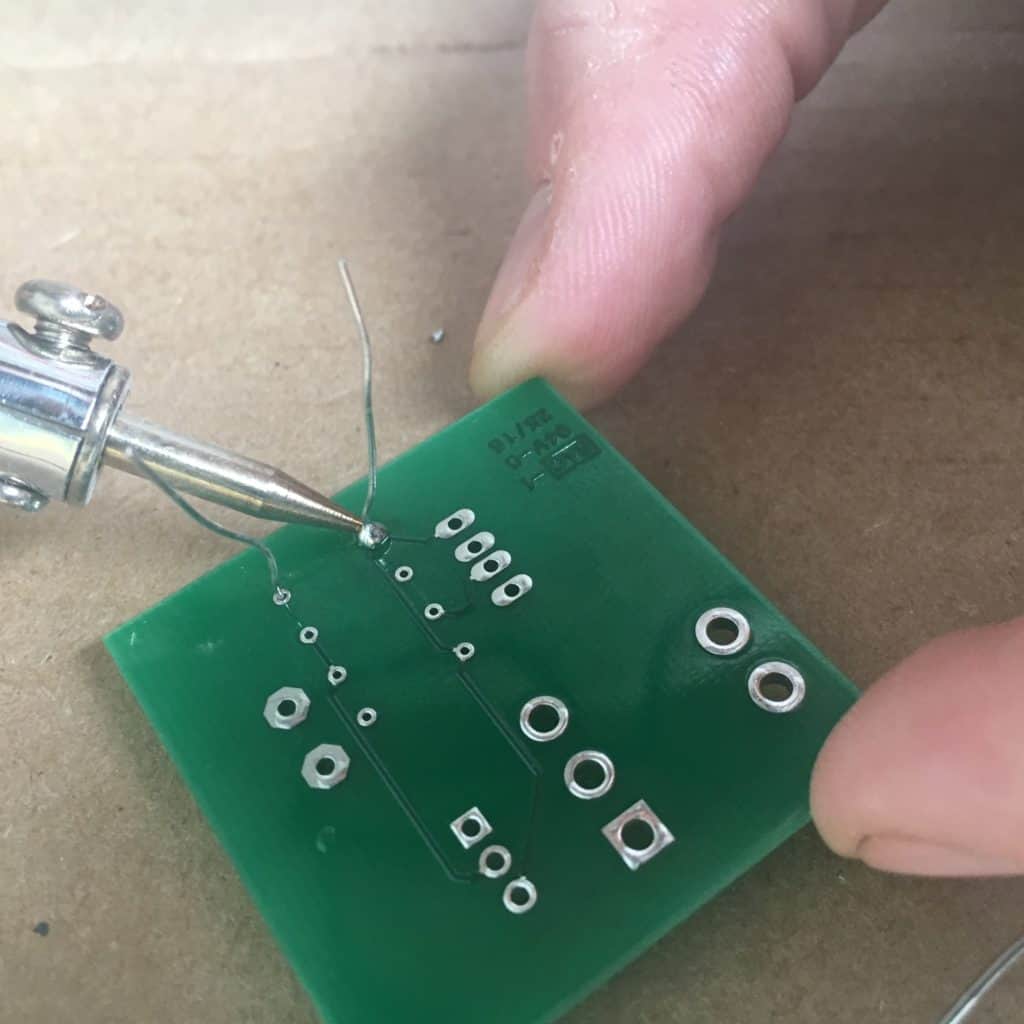

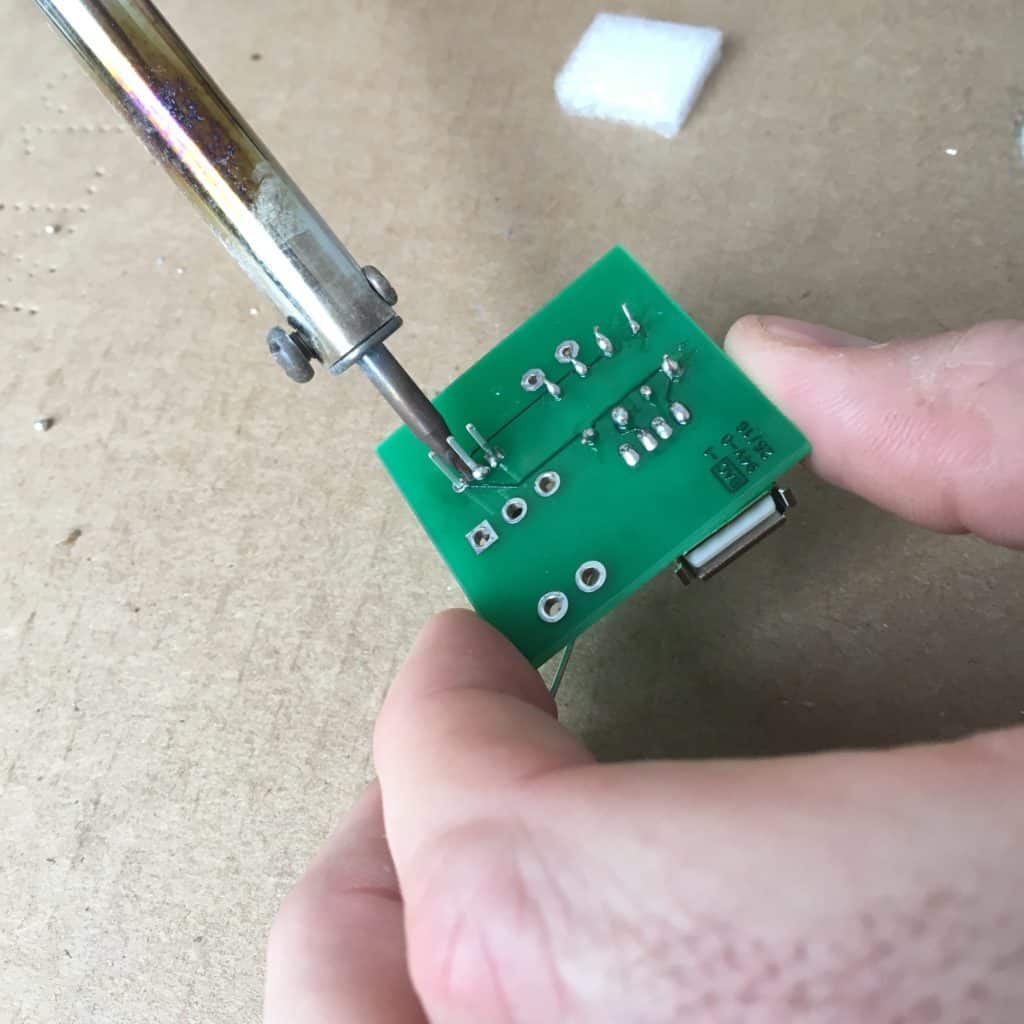

1. Solder R1 Resistor to Circuit Board

Begin by heating up the resistor wire without touching the solder directly. Try not to touch the PCB (green board) directly with your soldering iron – you don’t want to melt the board.

Point the soldering iron tip at the circular metal opening of the PCB and wait about 15-20 seconds then move the rosin core soldering wire onto the soldering iron.

You may need to go halfway up the soldering iron tip to get it started – it tends to be hotter towards the base of the iron.

The moment the wire melts is so cool.

You’re doing it right when the resistor leg wire gobs up like a raindrop and surrounds the leg, filling in the opening between the board and the resistor. When it’s liquid like this, try to move it into that opening space between the wire and the board.

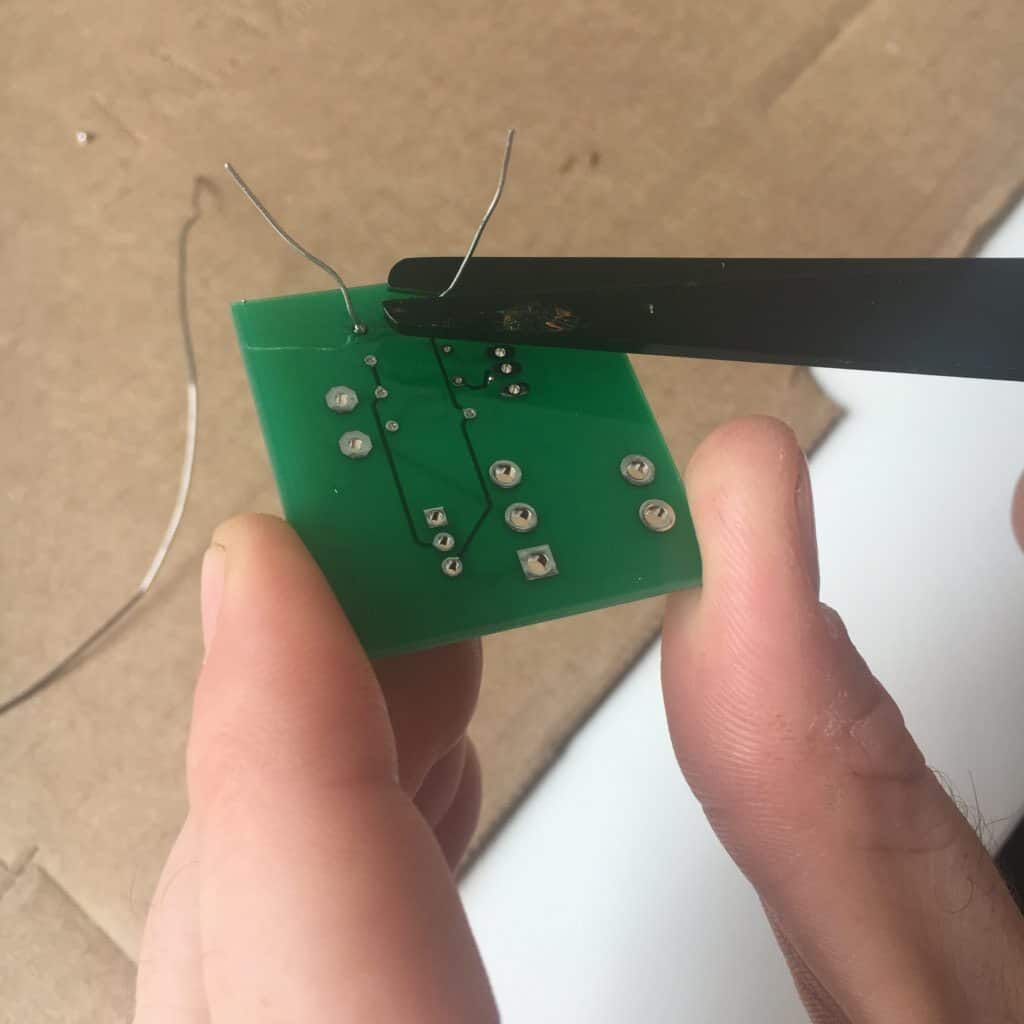

Trim the excess wire once the first resistor is soldered in.

Here’s how it looks after the first resistor is in – it’s a little sloppy, but it will get fixed in the end during touchups.

Make sure you are using your damp sponge!

You should occasionally see steam when you touch the soldering iron to the damp sponge.

2. Repeat Step 1 For The Remaining Three Resistors

Continue the soldering process for the three remaining resistors – double-check that they are going into the correct positions!

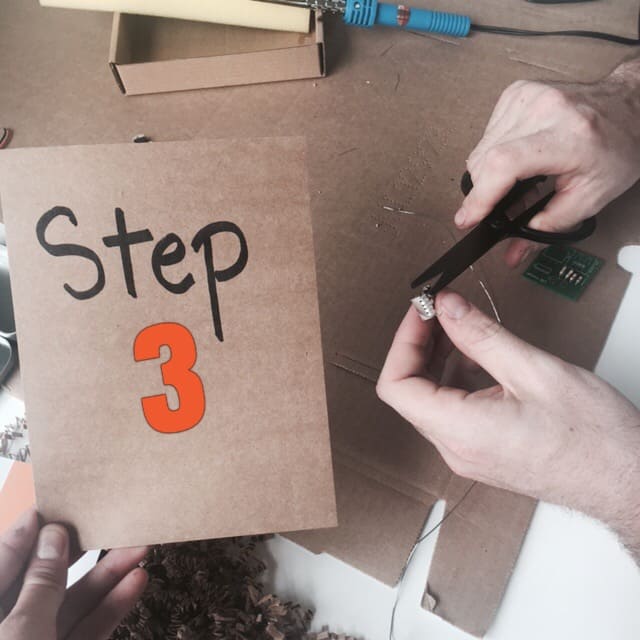

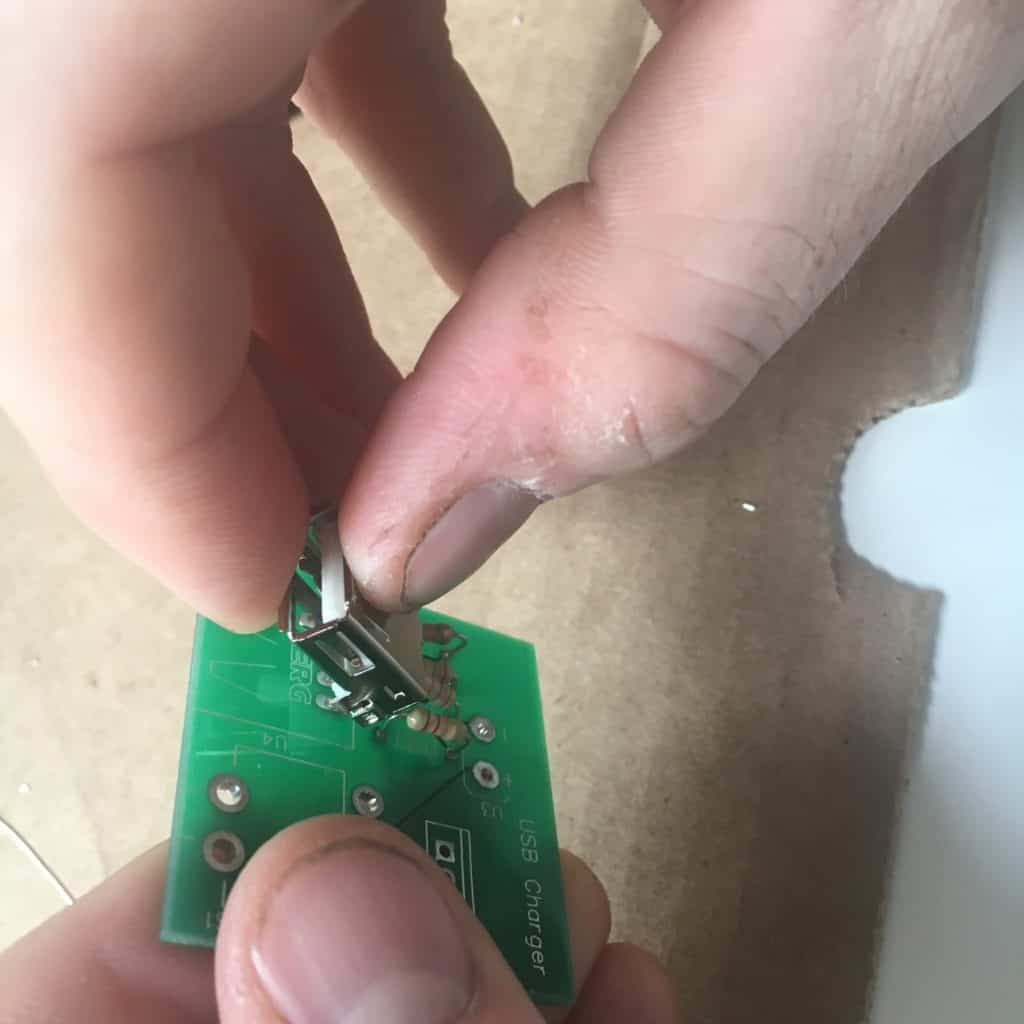

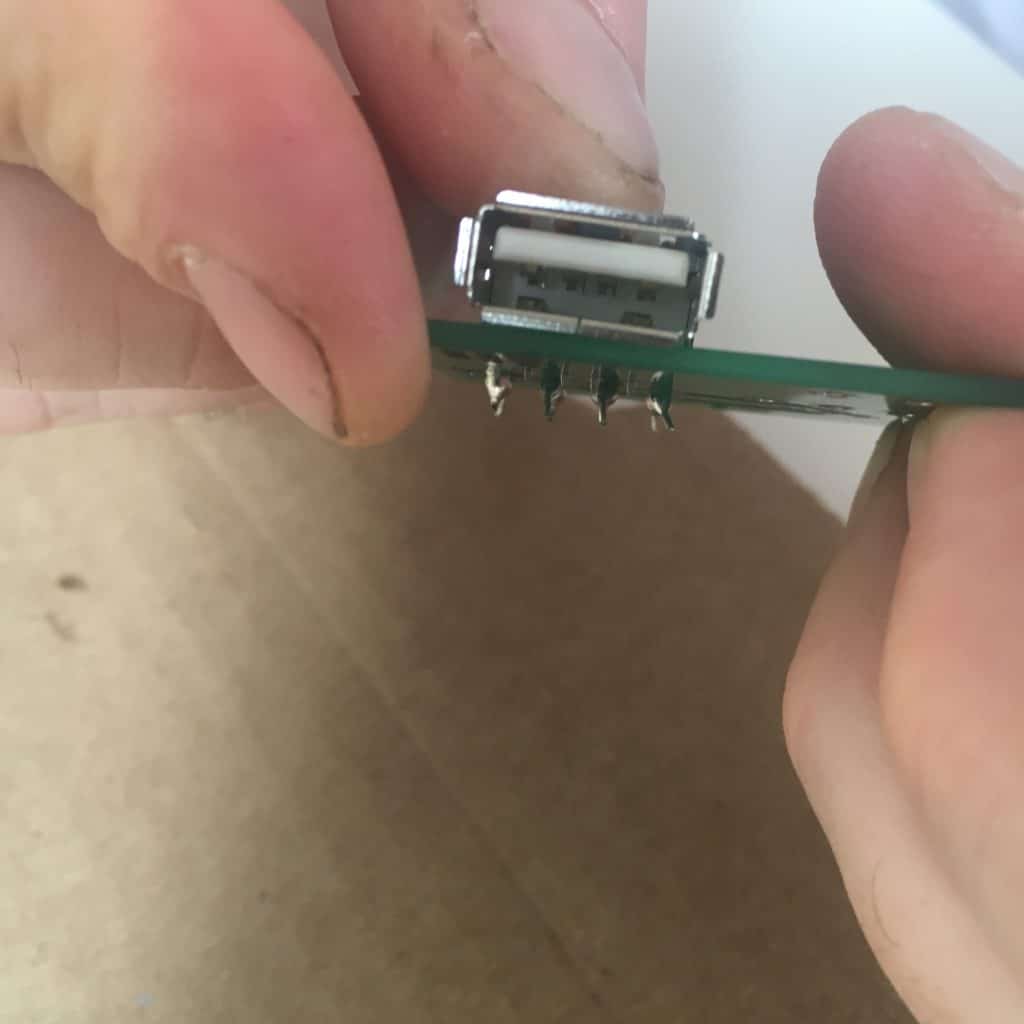

3. Connect USB Connector U4 to Circuit Board

Next up is the USB component – it’s the one that you would expect a USB port to look like.

There are tabs on each side of the connector that you will have to either cut off with wire cutters or bend back. I decided to cut them off and bent them first to make it easier to.

I would recommend you do the same – since the tabs of the USB connector are thick, it can be difficult to work around them if you leave them on.

If you don’t bend or cut the tabs on the side of the connector, the component won’t fit nicely to the board – so it’s better to get them out of the way before you attach it to the board.

You will solder the USB connector the same way you soldered the resistors

4. Solder Regulator U2 To The Circuit Board

This has to face a certain direction because it is polarized.

Simply put, place the mounting tab in the same direction as the stripe on the board. On the board, that’s the narrow rectangle attached to the larger rectangle – the metal piece on the regulator that’s about the same size will fit into that spot.

ONCE IN PLACE, SOLDER IT IN

Trim the prongs back a bit if you are looking for an easier way to navigate your soldering iron around this component.

Go ahead and get soldering!

On my build, there was a gap between the regulator, solder, and the PCB, so this was a good time to go back and melt it down and make sure there were no gaps in the work.

5. Connect Power Snaps To The Circuit Board

This one’s super easy. The important thing here is to make sure that the black wire is going to the negative pad and the red wire is going to the positive tab.

Solder away…

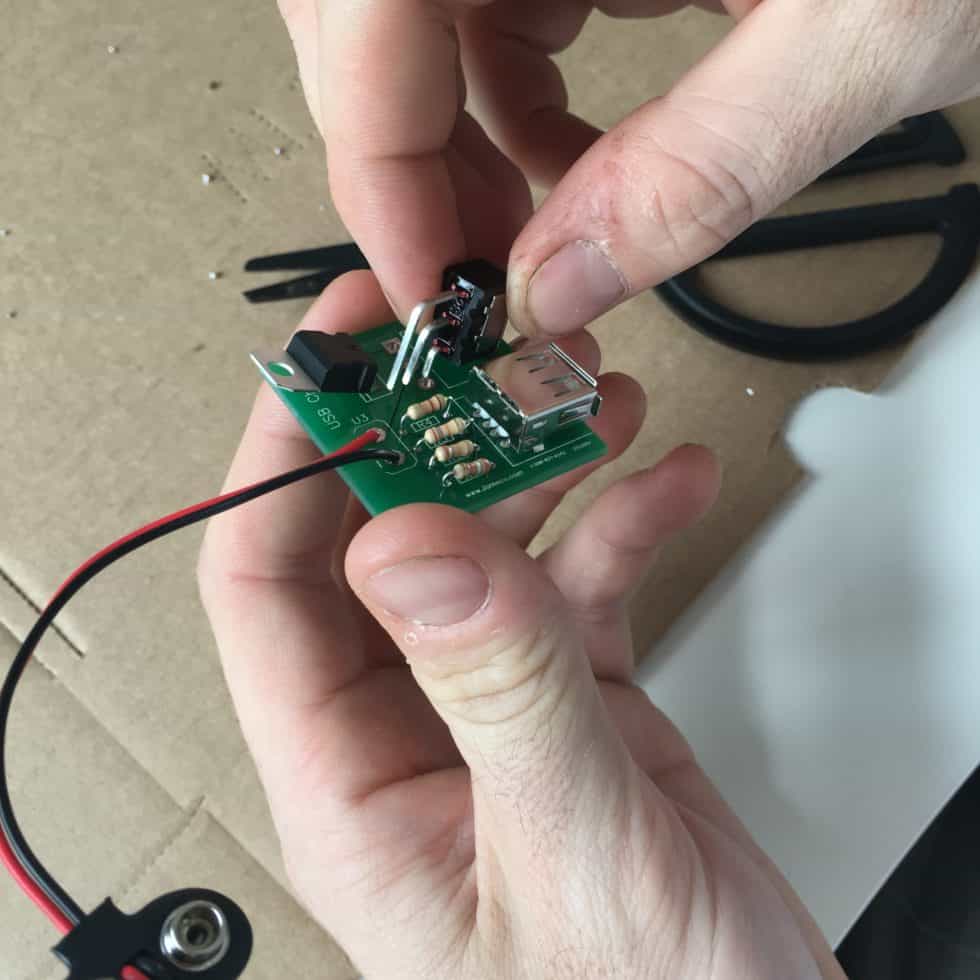

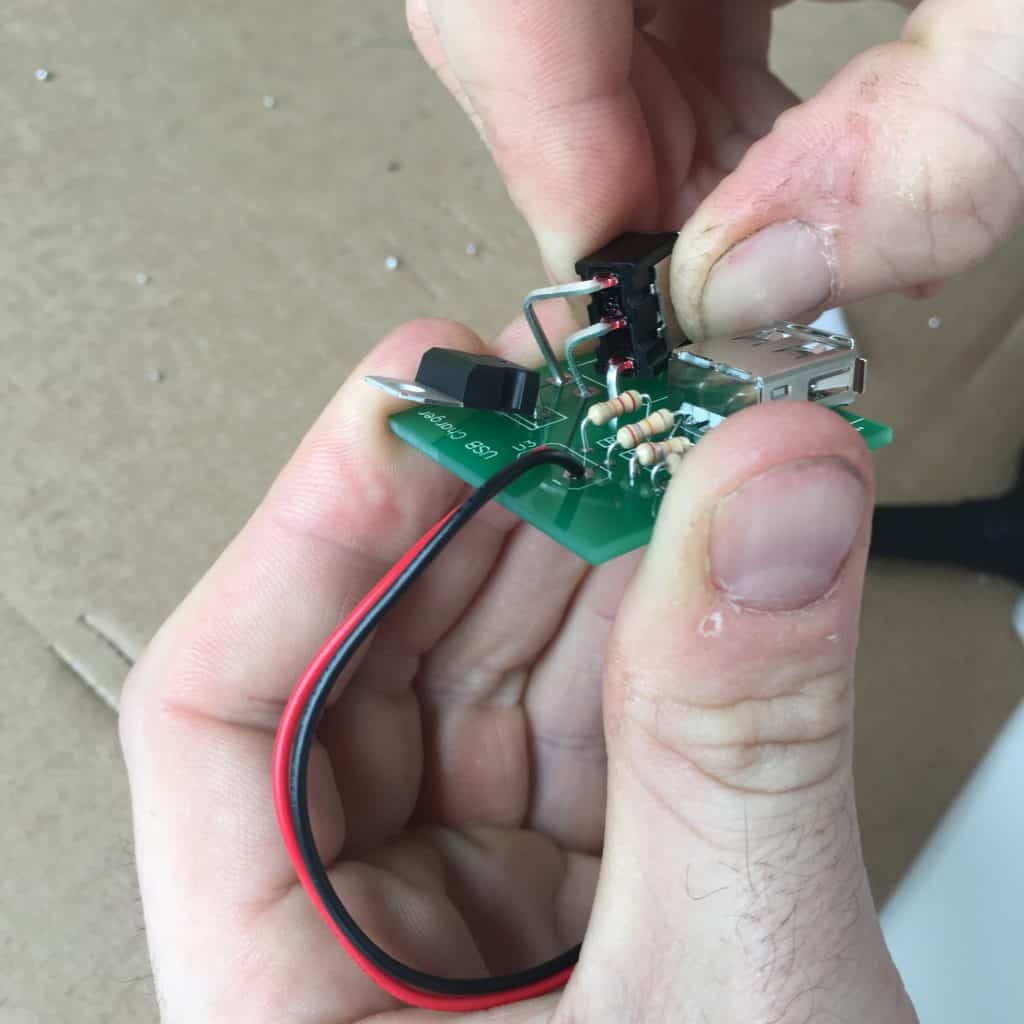

6. Solder The Toggle Switch To The Board

I found this step to be the most challenging – grab your pliers.

The toggle switch doesn’t fit nicely on the board

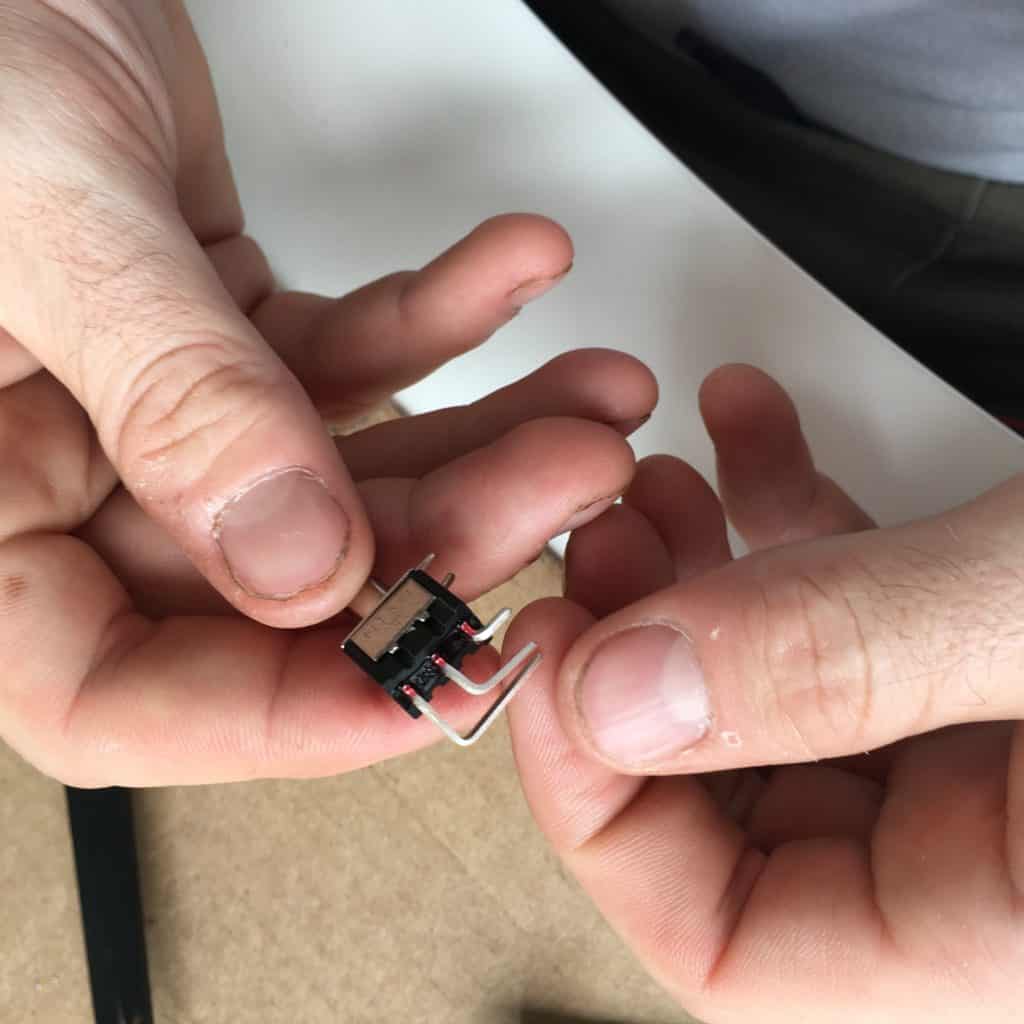

There are 5 prongs on this component. One set with two prongs, one set of three prongs. It needs to fit like the image below, but the 3 wires out the back don’t fit into their corresponding holes – see first image below.

You’ll see this is the way it’s supposed to sit, but doesn’t align to the gaps.

We have to use some muscle for this fix.

Bend the set with the three prongs – the visible prongs in the image above.

The shortest wire (one on the bottom of the component) of those three will go on the far left hole, so the other two need to bend back to the right. The middle will go in the middle hole, and the top wire will go to the far right.

You’ll need to use some force to bend this – just go slow and apply some pressure.

PLACE TOGGLE SWITCH ONTO PCB

Start by putting the front two prongs in their corresponding holes. Remember to use the front-facing side of the PCB.

Next, place the back three prongs in their spots. You may have to stretch the prongs a bit to get them to fit into place.

Bending this will shift the toggle at a slight angle, once it’s laid on the board, which is fine.

TEST IF IT’S FUNCTIONING PROPERLY

Grab a spare USB chord and find a device you want to test out.

Hook up the 9V battery and see what happens.

If you don’t notice a charge right away, hit the switch, you may be in the off position.

Did it work? Awesome! If not, check the toggle switch, and if that doesn’t work, troubleshoot with the following:

- Check that all soldering work is encasing the wires and components throughout the PCB. Remember, you don’t want any gaps in the spaces on the board.

- Check that your 9V battery was properly snapped on.

- Try your USB chord on another power source to make sure it’s not the chord.

- If you’re having issues, it’s most likely how the soldering was done around the board. Look closely – if you can’t figure it out, comment below and we can troubleshoot it together.

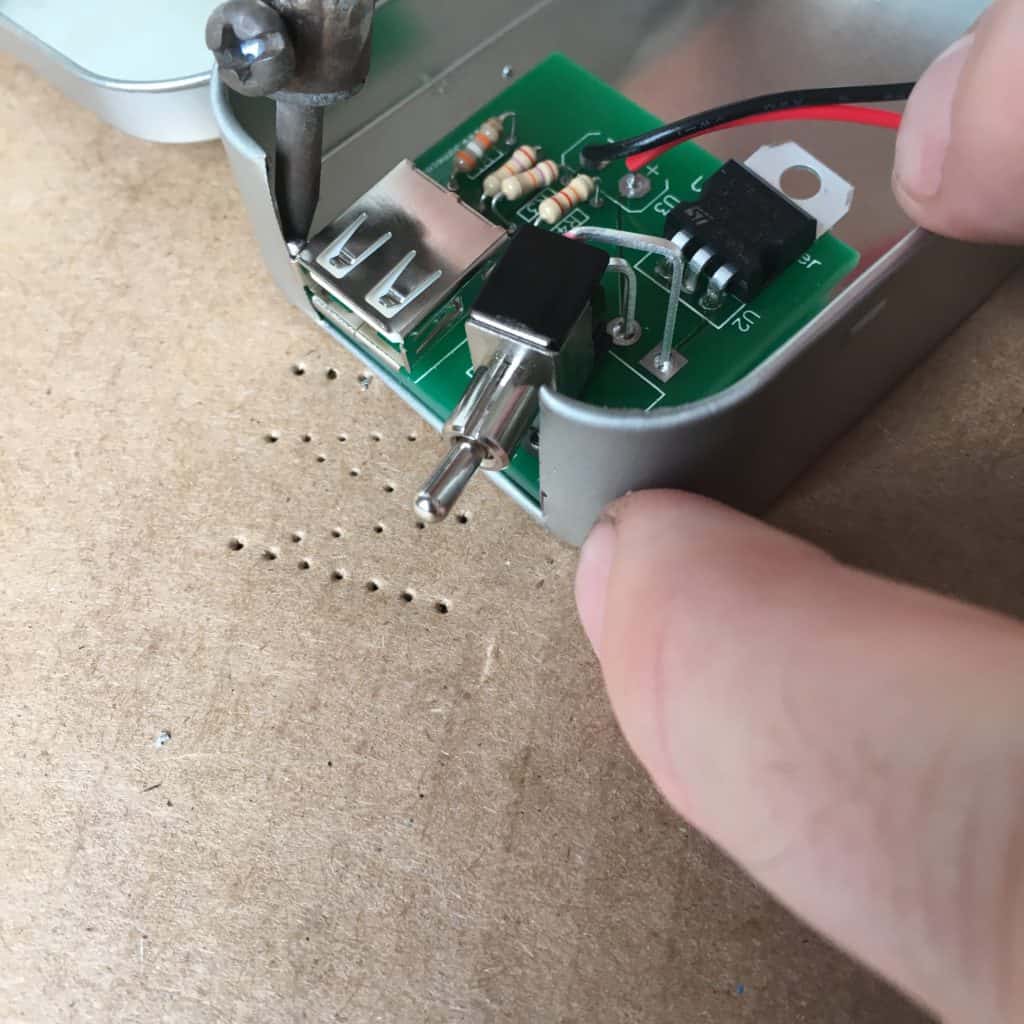

7. Time For The Altoids Tin

Cut a section out of your tin that will allow the USB charger to poke out the site. Be careful handling this part – this tin is sharp and can cut your fingers.

Begin folding that piece facing outwards – you’ll need your scissors here. Cut about 1/2″ off the piece. Take the remaining attached part and fold it back in.

Now, let’s place the electronics kit in its new tin home.

The board will sit on top of the lip of the folded tin piece.

DOES THE BOARD WIGGLE?

You should have enough solder left over to make sure it doesn’t wiggle out of the tin.

Two parts of the board and components can come in contact with the tin. The USB connector and the toggle switch. We will solder the connector to the tin

SOLDER COMPONENTS TO TRIMMED TIN AREA

This spot is perfect for connecting the board to the tin so it doesn’t shake around. Begin soldering the trimmed section to the tin.

The key here is to make sure the tin and the connector’s metal pieces are extremely hot before trying to apply solder.

Be sure you aren’t covering any opening to the USB port – instead, you will focus on the outside piece starting to bond with the tin housing.

ALTERNATIVES TO SOLDERING THE BOARD TO THE HOUSING

You can easily use electrical tape to connect the PCB to the tin inside, and that will keep it from moving around.

And That’s How You Solder A Portable USB Charger

You are now the proud owner of a portable USB charger, plus you’ve just learned the skill of soldering which is extremely cool.

Use it as a portable phone charger, or maybe a new way to convert batteries into a useful emergency power bank (useful as in AA and 5V batteries don’t typically charge USB devices.)

Either way, that’s the beauty of this kit – you can charge anything that has a USB.

SOLDERING ELECTRONICS INSPIRATION

Got the electronics bug and looking to take this hobby further? Check out some of the thought leaders in this field:

Look for electronics themed meetups in your area using meetup.com

If you have any sort of wood lying around, you’re in luck. Your soldering iron can also be used for wood burning! Soldering iron has many uses, and we encourage you to try some of them out.

We have a whole tutorial on wood-burning – AKA pyrography, so be sure to check that out once you’ve mastered your own portable phone charger.

In addition to wood, your soldering iron can burn onto suede, leather, and cork!!

Happy Hobbying!